Our Quality Control and Test Philosophy

We work to industry best-practice standards for Quality Control and Test, which we have refined and updated over 40 years. This philosophy means that, although we have comprehensive inspection and test procedures in place, we build quality into our processes rather than relying on inspection to catch problems once the assemblies are built

You can find out more about our inspection and test philosophy here.

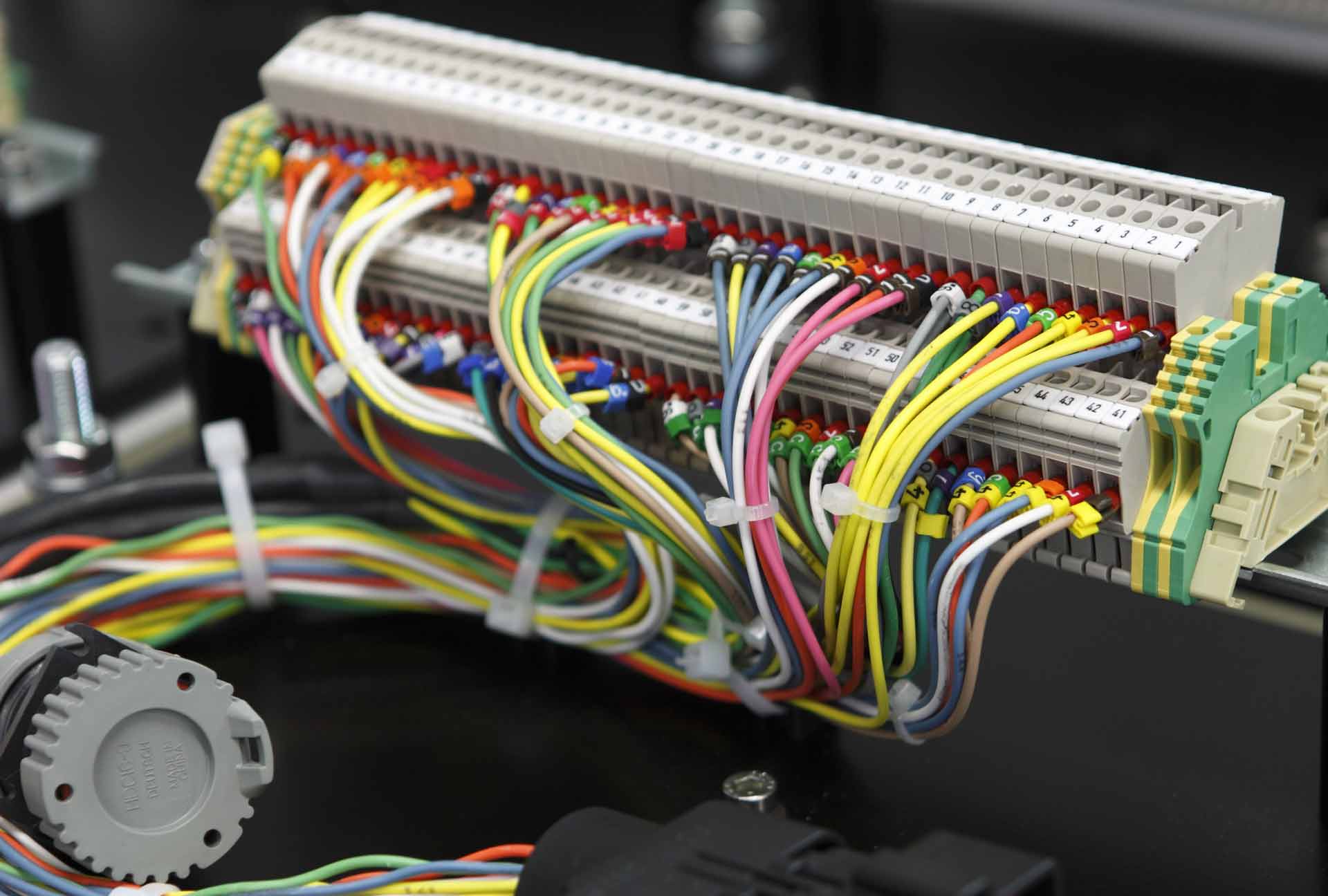

Our Inspection and Test Procedures

Everything we manufacture is visually inspected to drawing, in line with our ‘right first time’ Quality Control philosophy.

In addition, where appropriate and possible we perform:

- Continuity test with Automated equipment

- Flash test to check for potential shorts

- Dimensional checks

- Power-up tests on PCBs

- System tests on sub-assemblies and box builds

We provide further support through :

- PPAP – Production Part Approval Process

- FAI – First Article Inspection

We work to manufacturing acceptance standards IPC610 for PCB production, and IPC620 for all wiring assemblies and hold ISO9001 2015 approval.